Moisture Control

Kohler Coating focuses on creating advanced technology driven products that have a positive impact on the processes and production methods of our customers. Goettsch is proud to supply Kohler Coating equipment to the International Market*. Kohler Coating takes great pride in social responsibility by developing equipment that plays a major role in reducing Green House Gas Emissions and increasing overall sustainability within the corrugating and converting industries.

The Goettsch professionals are highly skilled in corrugated converting and can recommend the right equipment solution for your application, facility and budget, create efficiencies and provide on-going parts and service support.

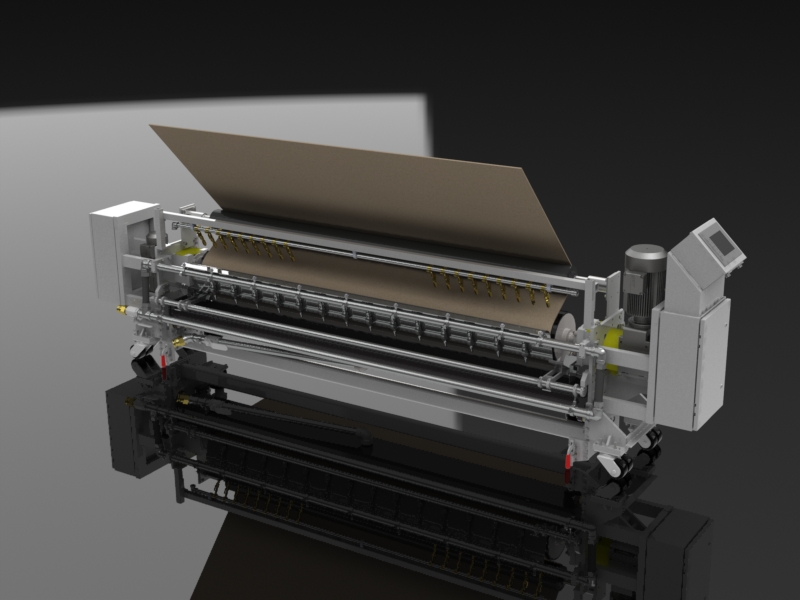

ISO-Bar Technology

An isobar is a line of constant pressure on a weather map. The Kohler ISO-Bar is a rod coater which applies equal metering pressure in a line across the entire width of the web. The ISO-Bar technology is what allows Kohler’s machines to radically reduce film thicknesses of starch or other fluids, giving you the ability to accurately meter film thicknesses lower than .0002 inches (5 microns)!

ISO-Bar WaterDeck™

Precision moisture control technology

The Importance of Moisture Control

Moisture is the leading cause of warp and washboarding in corrugated board. Managing and controlling moisture in the corrugating process is critical to producing flat, smooth board.

The WaterDeck gives you precision control of the moisture applied to the liners. You have total control to put it precisely where it’s needed and in the precise amount that’s necessary.

- Saves energy and glue, enhances productivity and quality

- Produce corrugated board that’s not only flat and smooth, but stays flat and smooth!

-

Eliminates score cracking

-

Prevents damage to sensitive or coated papers

-

Makes stronger, stiffer board

* Available to specific countries; please consult with Goettsch International for availability.