Consumables

The knowledgeable Goettsch parts sales staff, conversant in multiple languages, is ready to research your specific requirement, provide up-to-date technical data and do whatever it takes to keep your business running smoothly.

High Temperature Lubricants

DuPont™ Krytox® performance lubricants have become the corrugator industry standard for lubricating bearings on heated rolls in single facers and associated equipment. Recommended by Sun Automation for Langston Single Facer conversions.

Also available is the DuPont™ Krytox® NSF H-1 Food Grade Certified performance lubricant. Two available grades to provide you with peace of mind and full confidence that Krytox greases are non-toxic, and completely biologically and environmentally inert, and recommended for use in the manufacture of food packaging materials where an H-1 rated lubricant is required.

Fully Annealed Automatic Baling Wire

- Strong enough to contain a compressed bale

- Ductility to twist five times or more to make a secure knot

- Consistent diameter with no hard spots

- Recommended by the American Baler Company!

- 100 lb. (45 kgs) box coils for balers with automatic tiers

- Single loop bale ties for hand-tied baling

- 1000 lb. (450 kg) coils for large scale paper recycling operations

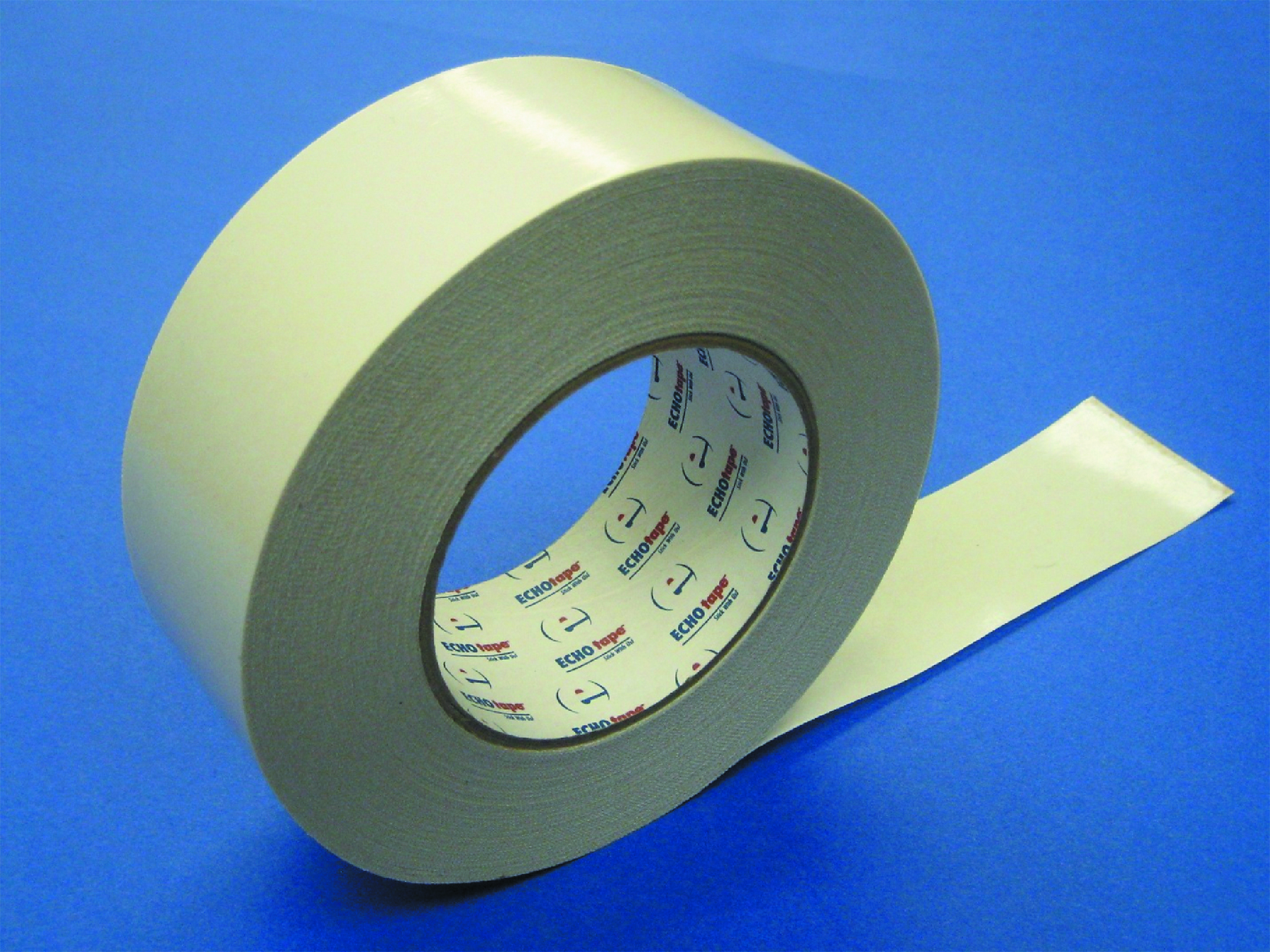

High Performance Splicing Tape

Goettsch offers a 3.9 mils thick, non-woven tissue, double coated high performance splicing tape with an aggressive, high tack, high heat resistant, acrylic pressure sensitive adhesive. Our tape provides excellent quick stick and holding power and is ideally suited for high speed flying splice applications.

|

Technical Data

|

|

Thickness Without Liner

|

3.90 mils (.1mm)

|

|

Carrier

|

Tissue

|

|

Liner

|

White

|

|

Adhesive

|

Acrylic

|

|

Adhesion

|

63 oz/in (4.5 kg/cm)

|

|

Temperature Application Range

|

15~25°C (59~77°F)

|

|

Operating Temperature

|

-20°C to 130°C (-4°F to 266°F)

|

|

Color

|

Translucent

|

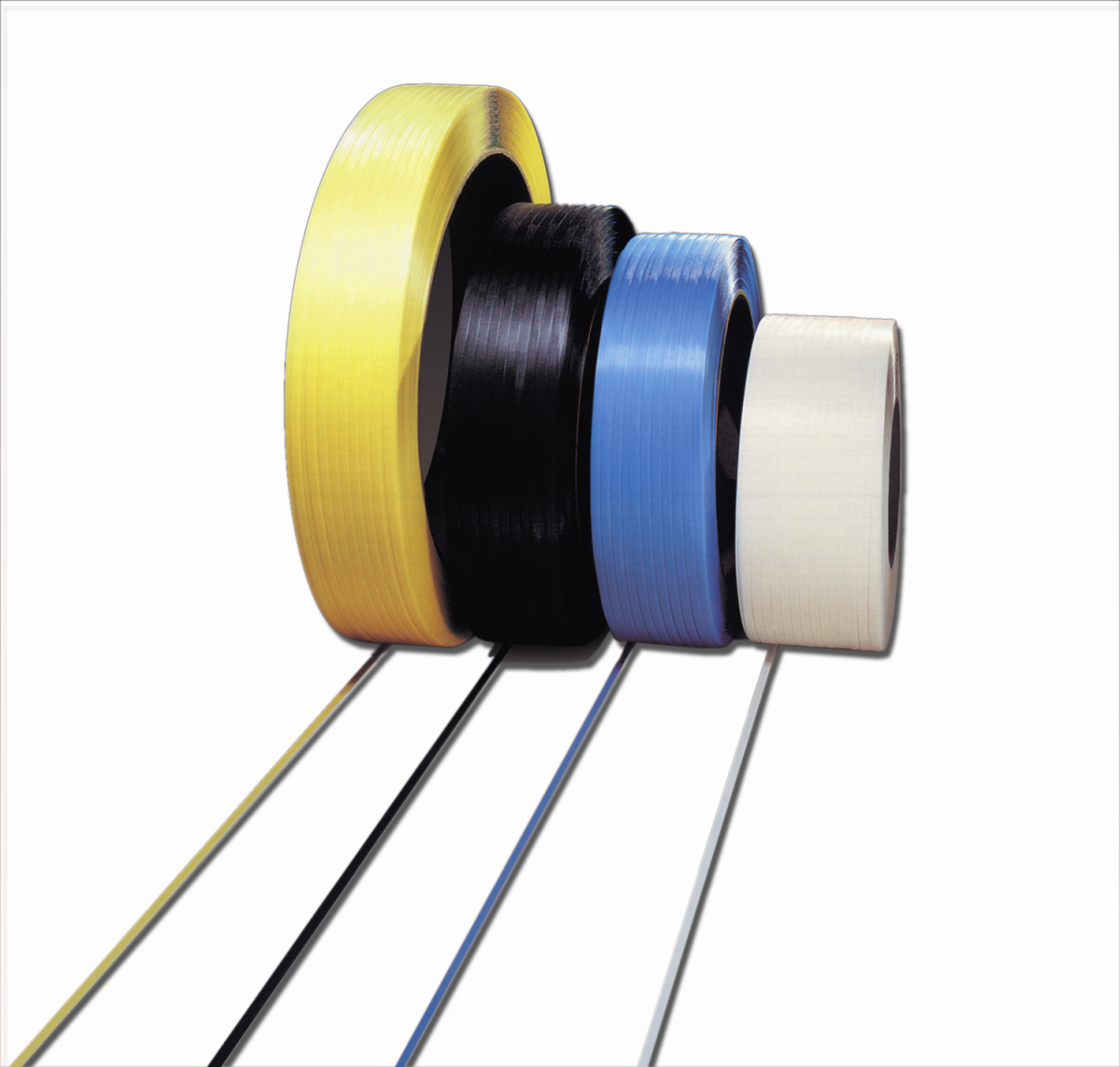

High Quality Strapping

For Signode, Mosca, Transpak and Others!

Quality

Offering an extensive line of polypropylene and polyester strapping materials made to the highest standards on state-of-the-art strap manufacturing lines to ensure the production of high-quality strap.

Manufacturing

Our supplier uses an extruded, embossed, strand process in the manufacture of its polypropylene and polyester strapping materials. Strapping manufacturing processes are geared to produce strap with the correct weight, thickness, width and camber and dusting limits for optimal performance in your equipment.

How to Order Strapping:

Contact your Goettsch Parts Representative with your material type (PE or PP) along with width and quantity to request a quote.

Running out of stock is costly and can lead to missed deliveries!

Ask about container load quantity pricing and our blanket order programs with regularly scheduled shipping!